Providing High-Quality Plastic Materials

Through Proprietary Technology and Advanced Equipment

Technology

TechnologyWhile leveraging expertise cultivated since our founding in 1969, we develop products using technologies that incorporate the latest market needs. Through careful compounding techniques and temperature control, we provide high-quality pellets backed by thorough quality management.

Custom Blending Technology

We meticulously blend materials to meet the specific properties and detailed requirements our customers desire. For compound formulations, our quality control department conducts preliminary in-house testing and creates sample materials for customer evaluation before developing raw materials that precisely match customer specifications.

Temperature Control for

Quality Assurance

If temperatures are too low, resins won’t dissolve properly; if too high, resins may degrade.

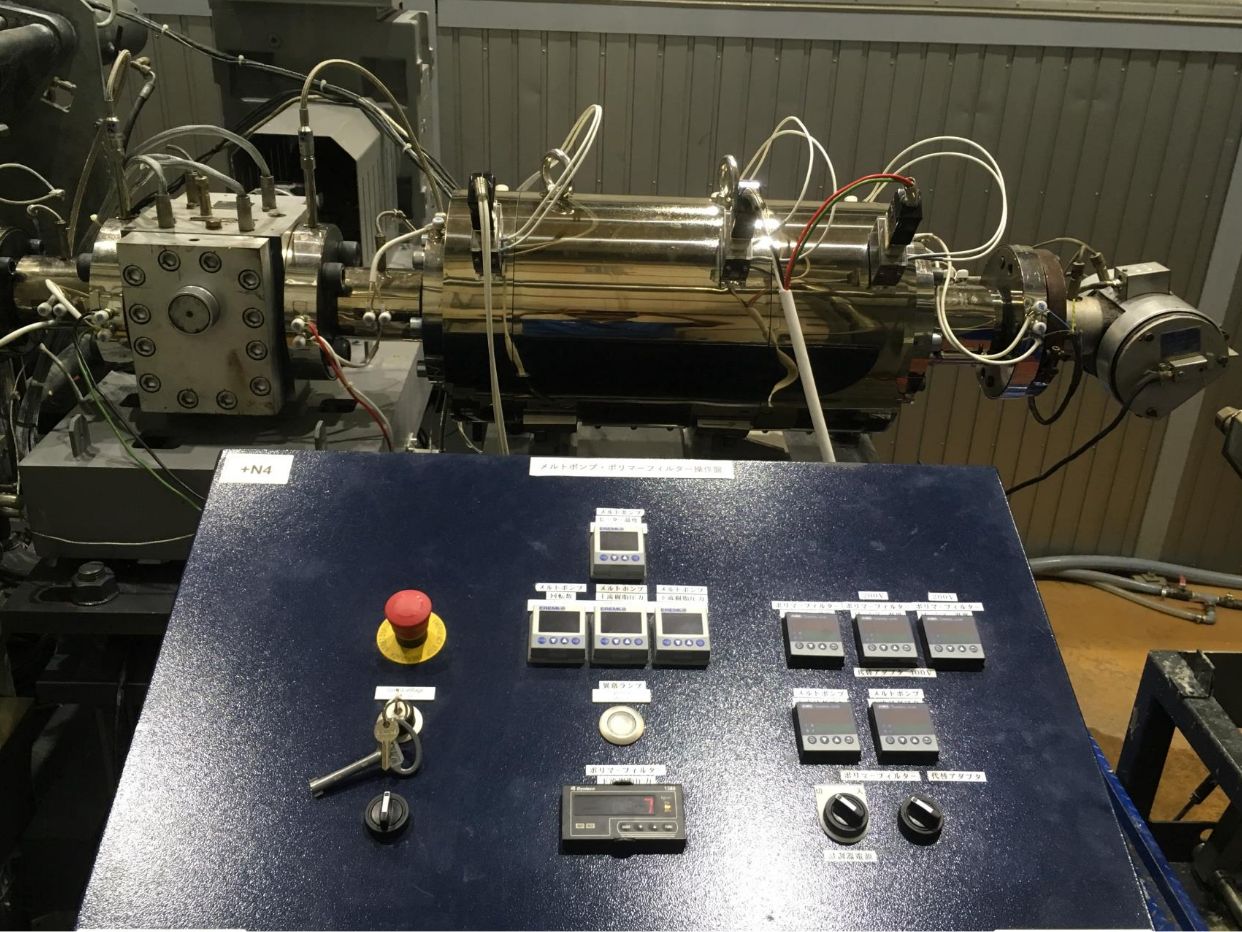

Toyo Chemical enforces strict temperature control and has implemented specialized screw designs that minimize resin degradation and polymer filters that remove fine foreign objects and contaminants. These measures create a system for consistently producing high-quality plastic materials.

Toyo Chemical enforces strict temperature control and has implemented specialized screw designs that minimize resin degradation and polymer filters that remove fine foreign objects and contaminants. These measures create a system for consistently producing high-quality plastic materials.

Thorough Quality Control System

We maintain strict quality control at every stage of production. During grinding, metal detectors check for foreign objects in raw materials. In extrusion, temperature is carefully managed, and operators monitor machinery to prevent pressure surges from contamination. Finished products undergo regular sampling, with each pellet carefully inspected for color inconsistencies, air bubbles, and other defects to ensure consistent quality.

Research & Technological

Advancements

As demand for recycled plastics evolves, we stay ahead through active research and development, ensuring continuous improvement and alignment with customer needs and industry trends.

Equipment

EquipmentTo provide high-quality pellets, we source high-performance machinery directly from Austria, customizing it to meet specific customer needs. This allows us to develop products tailored to exact requirements.

〜 Industry First! 〜

Polymer Filter Installation on

Recycling Machines

We are capable of handling contract-based optical film recycling. Continuous contaminant removal enables the production of 10μm cut materials (filtration precision of 10μm), ensuring higher quality recycled products. Our 24-hour operations provide stable, high-quality production.

Foreign Objects Sorting Machine

Supporting High-Performance

Resin Quality

Using the top model of foreign objects sorting machines, achieving high detection precision (0.03mm resolution) and compatibility with transparent materials through innovative lighting methods. Detects and removes defects such as black spots and discolored particles to support quality improvement of plastic raw materials.

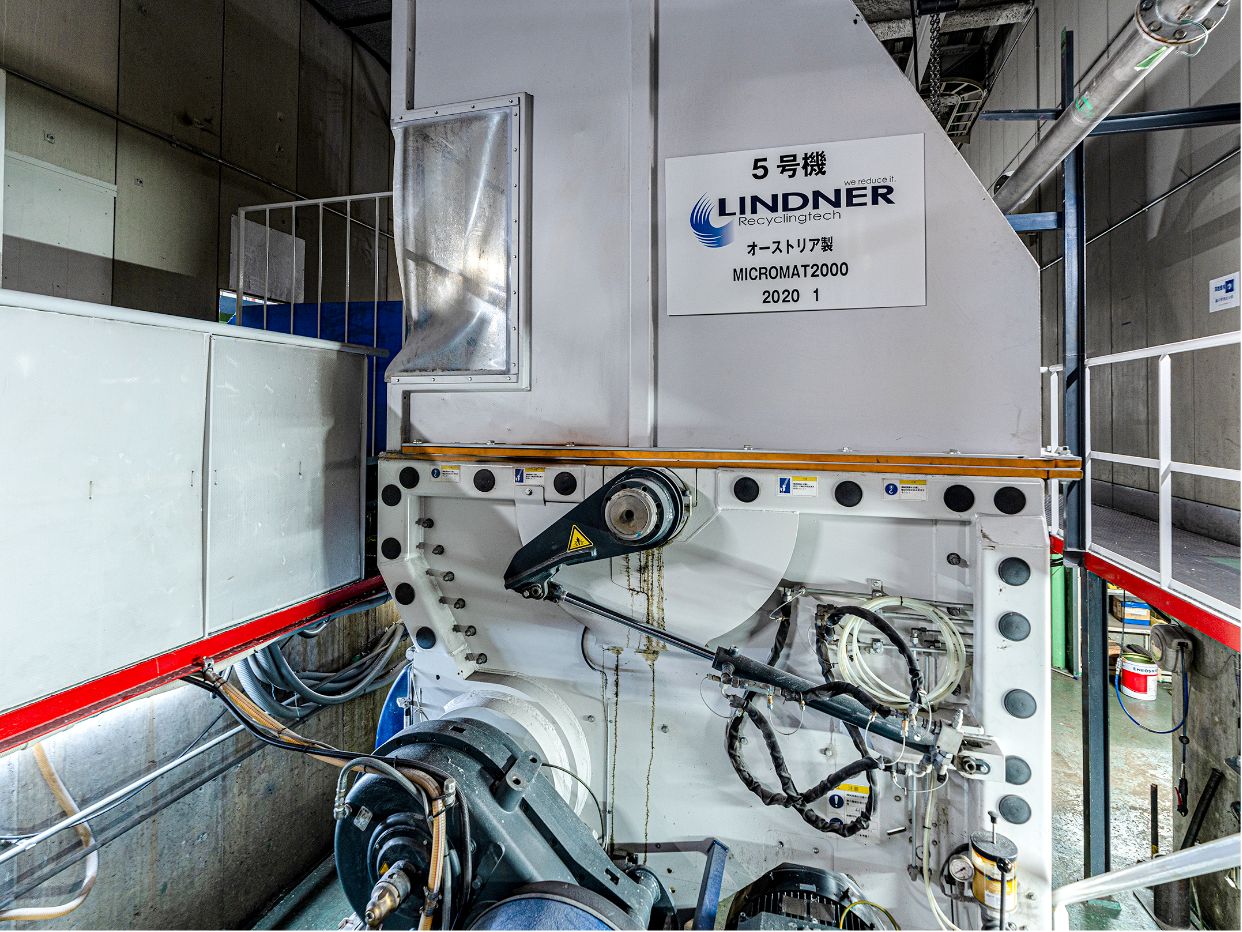

Latest Grinding Machine Capable of Grinding Over 2 Tons Per Hour

Grinds collected and sorted polyolefin resin materials with the latest equipment and machinery.

With advanced crushers capable of sufficiently processing recyclable materials

that are typically too hard or too soft for normal grinding, we can process over 100 tons daily.

With advanced crushers capable of sufficiently processing recyclable materials

that are typically too hard or too soft for normal grinding, we can process over 100 tons daily.

High-Performance Customized Extrusion Machine Imported

from Austria

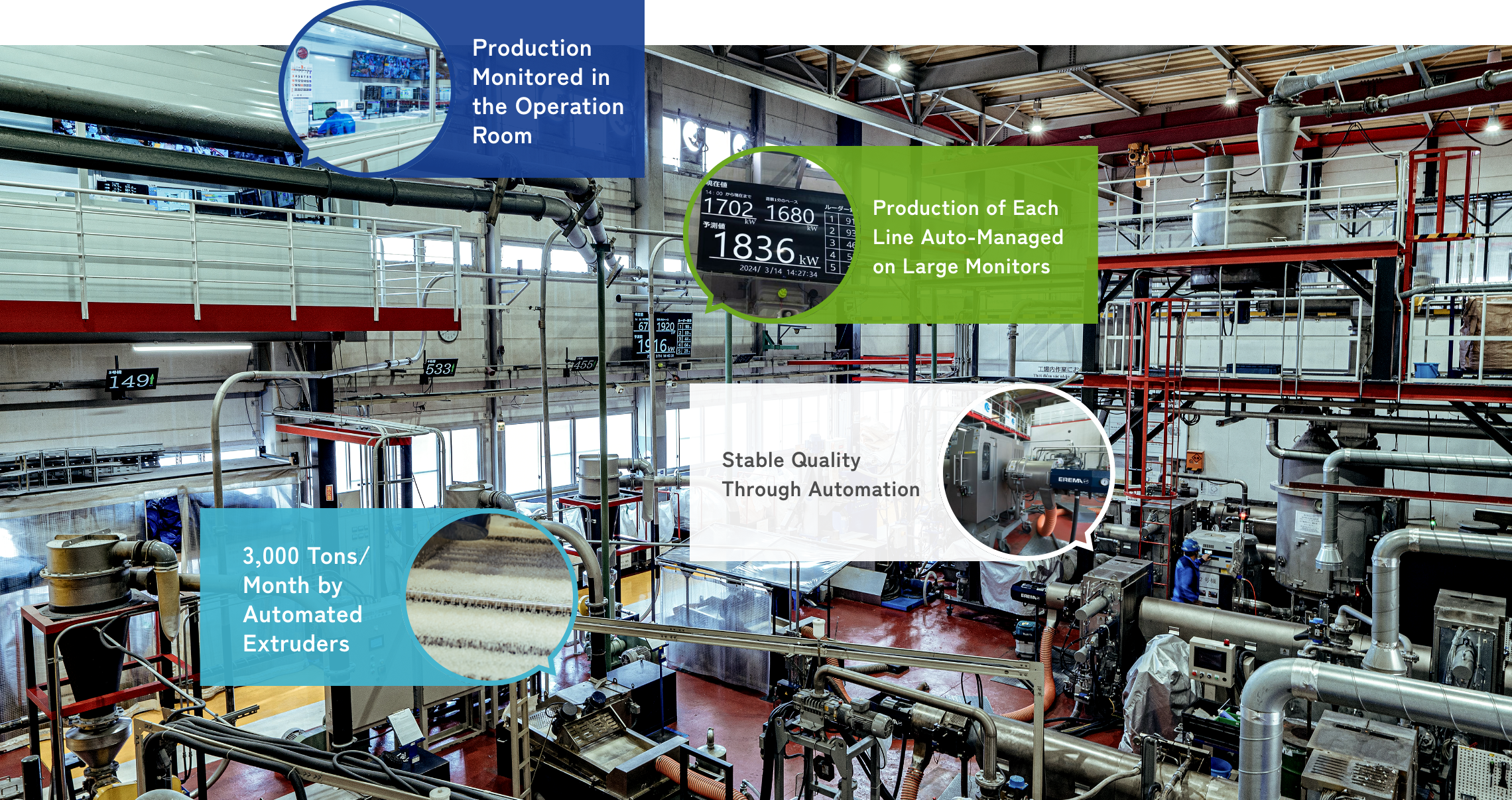

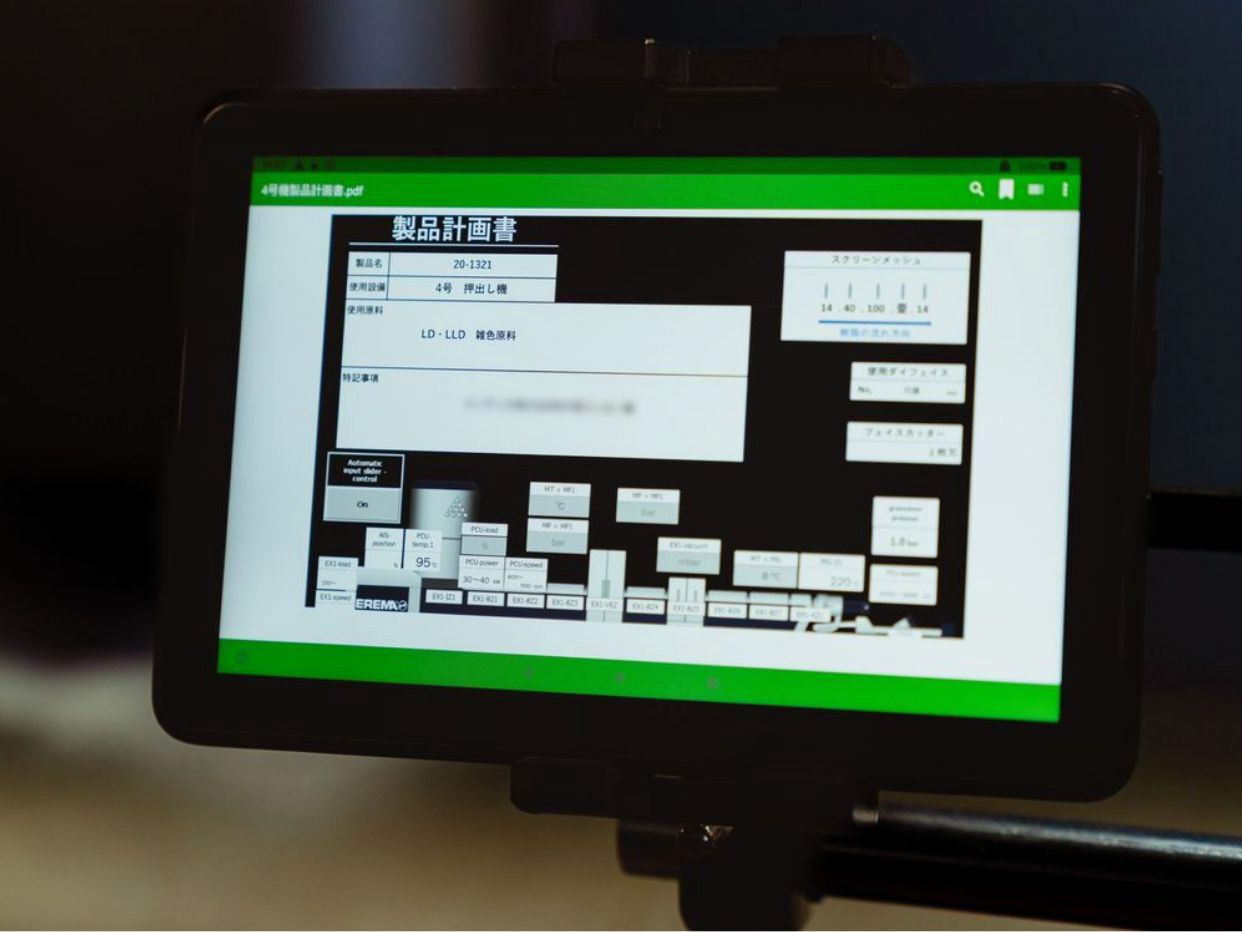

Early industry adoption of high-performance extruders since June 1994. Imported from Austria and uniquely customized to meet customer requirements, these are rare facilities in Japan. With 24-hour full operation capability through automation, we currently manufacture 3,000 tons of recycled pellets monthly, one of the largest capacities in Japan.

Remote Production

Management from

Operation Room

Toyo Chemical is advancing automation in production processes to improve quality and productivity. Currently, 6 out of 8 production lines are managed from the operation room, overseeing quality and production management. We will continue working toward further automation.

Smart Factory Initiatives

Installation of One of Japan’s

Largest 13-Ton Blenders

The Shimouchi Factory is equipped with a ribbon-type horizontal mixer capable of blending up to 13,000kg of plastic raw materials. We deliver homogenized materials with consistent quality.

Artificial Wood Molding Machine

Through our proprietary extrusion press molding machine, we are working to commercialize environmentally conscious civil engineering materials. We actively promote the use of used plastic products as materials to reduce plastic waste.

Equipment List by Factory

Main Factory

| Extruder | |||||

|---|---|---|---|---|---|

| Equipment Name | Manufacturer | Model | Year of Manufacture |

Screw | Screw Motor |

| Extrusion Machine No.1 | EREMA (Austria) | INTAREMA 1310TVE plus | 2019 | 100㎜ in diameter L/D55 | 160kW(217PS) |

| Extrusion Machine No.2 | EREMA (Austria) | INTAREMA 1310TVE plus | 2015 | 100㎜ in diameter L/D57 | 160kW(217PS) |

| Extrusion Machine No.3 | EREMA (Austria) | INTAREMA 1310TVE plus | 2022 | 100㎜ in diameter L/D57 | 250kW(339PS) |

| Extrusion Machine No.4 | EREMA (Austria) | INTAREMA 1310TVE plus | 2018 | 100㎜ in diameter L/D55 | 160kW(217PS) |

| Extrusion Machine No.5 | EREMA (Austria) | INTAREMA 1310TVE plus | 2017 | 100㎜ in diameter L/D55 | 160kW(217PS) |

| Extrusion Machine No.7 | EREMA (Austria) | PC1310TE | 2007 | 100㎜ in diameter L/D38 | 90kW(122PS) |

| Extrusion Machine No.8 | EREMA (Austria) | PC1310TE | 2009 | 100㎜ in diameter L/D38 | 150kW(203PS) |

| Extrusion Machine No.9 | EREMA (Austria) | PC1512T(E)-DD | 2010 | 120㎜ in diameter L/D36 | 160kW(217PS) |

| Crusher & Grinder | ||||

|---|---|---|---|---|

| Equipment Name | Manufacturer | Model | Year of Manufacture |

Screw Motor |

| No.1 | EREMA (Austria) | MICROMAT 2000 | 2018 | 132kW(180PS) |

| No.2 | LINDNER (Austria) | MICROMAT 2000 | 2012 | 132kW(180PS) |

| No.3 | LINDNER (Austria) | MICROMAT 2000 | 2021 | 132kW(180PS) |

| No.4 | LINDNER (Austria) | MICROMAT 2000 | 2014 | 132kW(180PS) |

| No.5 | LINDNER (Austria) | MICROMAT 2000 | 2020 | 132kW(180PS) |

| No.7 | Rapid (Sweden) | G600-90k | 2008 | 75kW(102PS) |

| No.8 | Rapid (Sweden) | G600-90k | 2006 | 55kW(75PS) |

| No.9 | Rapid (Sweden) | G600-120K | 2010 | 90kW(122PS) |

| Tumbler |

|---|

| Equipment Name |

| 3t Tumbler |

| 1t Tumbler |

| Inspection & Testing Equipment | ||

|---|---|---|

| Equipment Name | Manufacturer | Model |

| Melt Indexer | Takara Industry | L202 |

| Melt Indexer | TOYO SEIKI Co., Ltd. | F-F01 |

| Automatic Density Meter | TOYO SEIKI Co., Ltd. | D-H100 |

| Strogograph | TOYO SEIKI Co., Ltd. | VE10-D |

| Digital Impact Tester | TOYO SEIKI Co., Ltd. | DG-UB |

| Rockwell Hardness Tester | TOYO SEIKI Co., Ltd. | E |

| Muffle Furnace | Yamato Scientific Co., Ltd. | FO100 |

| Karl Fischer Titrator | Mitsubishi Chemical Corporation | CA100/VA100 |

| Fluorescent X-ray Analyzer | Shimadzu Corporation | EDX-720 |

| Electron Microscope | Moritex Corporation | MSX-500Di |

| Differential Scanning Calorimeter | SII Nanotechnology Inc. | DSC6220 |

| 40㎜ Extrusion Machine | Sun Engineering | SEG-40V |

| 150mm Film Extrusion Machine | Sun Engineering | STU300 |

| 50t Injection Molding Machine | Japan Steel Works, Ltd. | J50SBⅡ |

| 40㎜ Blow Molding Machine | Chubu Chemical Engineering Works, Ltd. | TK-40 |

| Small Pulverizer | Kato Riki Seisakusho Co., Ltd. | KRF-30 |

| Compression Molding Machine | Shindo Metal Works Co., Ltd. | NF-30 |

| Fully Automatic Viscosity Measurement Device | Rigōsha Co., Ltd. | VMS-022UPC |

| Inflation Molding Machine | Placo Co., Ltd. | L-40A |

Shimouchi factory

| Crusher | ||||

|---|---|---|---|---|

| Equipment Name | Manufacturer | Model | Year of Manufacture |

Screw Motor |

| Extrusion Machine No.1 | Horlai (Japan) | M-840 | 1973 | 55kW(75PS) |

| Extrusion Machine No.2 | Horlai (Japan) | ZQJCH3 | 2016 | 75kW(102PS) |

| Extrusion Machine No.3 | Horlai (Japan) | ZN205 | 2003 | 90kW(122PS) |

| Blender | |||

|---|---|---|---|

| Equipment Name | Manufacturer | Model | Year of Manufacture |

| 13t Blender | DEOR-DING (Taiwan) | ー | 2017 |

| 5t Blender | DEOR-DING (Taiwan) | ー | 2016 |

| Grash Mixer | ||||

|---|---|---|---|---|

| Equipment Name | Manufacturer | Model | Year of Manufacture |

Motor |

| Grash Mixer | Sanko Sangyo Co., Ltd. (Japan) | ー | 1984 | 110kW(150PS) |

| Molding Machine | |||||

|---|---|---|---|---|---|

| Equipment Name | Manufacturer | Model | Year of Manufacture |

Theoretical Injection Volume |

Clamping System |

| Electric Servo Injection Molding Machine | Sanko Sangyo Co., Ltd. (Japan) | Si-450-6S/K600E | 2019 | 2028㎤ | Double Toggle |

| Electric Servo Injection Molding Machine | Sanko Sangyo Co., Ltd. (Japan) | Si-180S | 1999 | 201㎤ | Double Toggle |

Mino factory

| Extruder | |||||

|---|---|---|---|---|---|

| Equipment Name | Manufacturer | Model | Year of Manufacture |

Screw | Screw Motor |

| Extrusion Machine No.10 | EREMA (Austria) | RM120TE | 1997 | 120㎜ in diameter | 160kW(217PS) |

| Extrusion Machine No.11 | EREMA (Austria) | RGA100TVE | 1996 | 100㎜ in diameter | 132kW(180PS) |

| Crusher | |||

|---|---|---|---|

| Manufacturer | Model | Year of Manufacture | Motor |

| WEIMA(German) | WLK 1500 |

2010 | 90kW(122PS) |

| Molding Machine | ||||

|---|---|---|---|---|

| Equipment Name | Manufacturer | Model | Year of Manufacture |

Screw Motor |

| Extrusion Injection Molding Machine | Chuou Kikai Corporation | VC100 | 1972 | 75kW (102PS) |