SMART

FACTORY

About Toyo Chemical

Smart Factory Initiatives

SMART

FACTORY

We are promoting automation to consistently deliver higher quality products

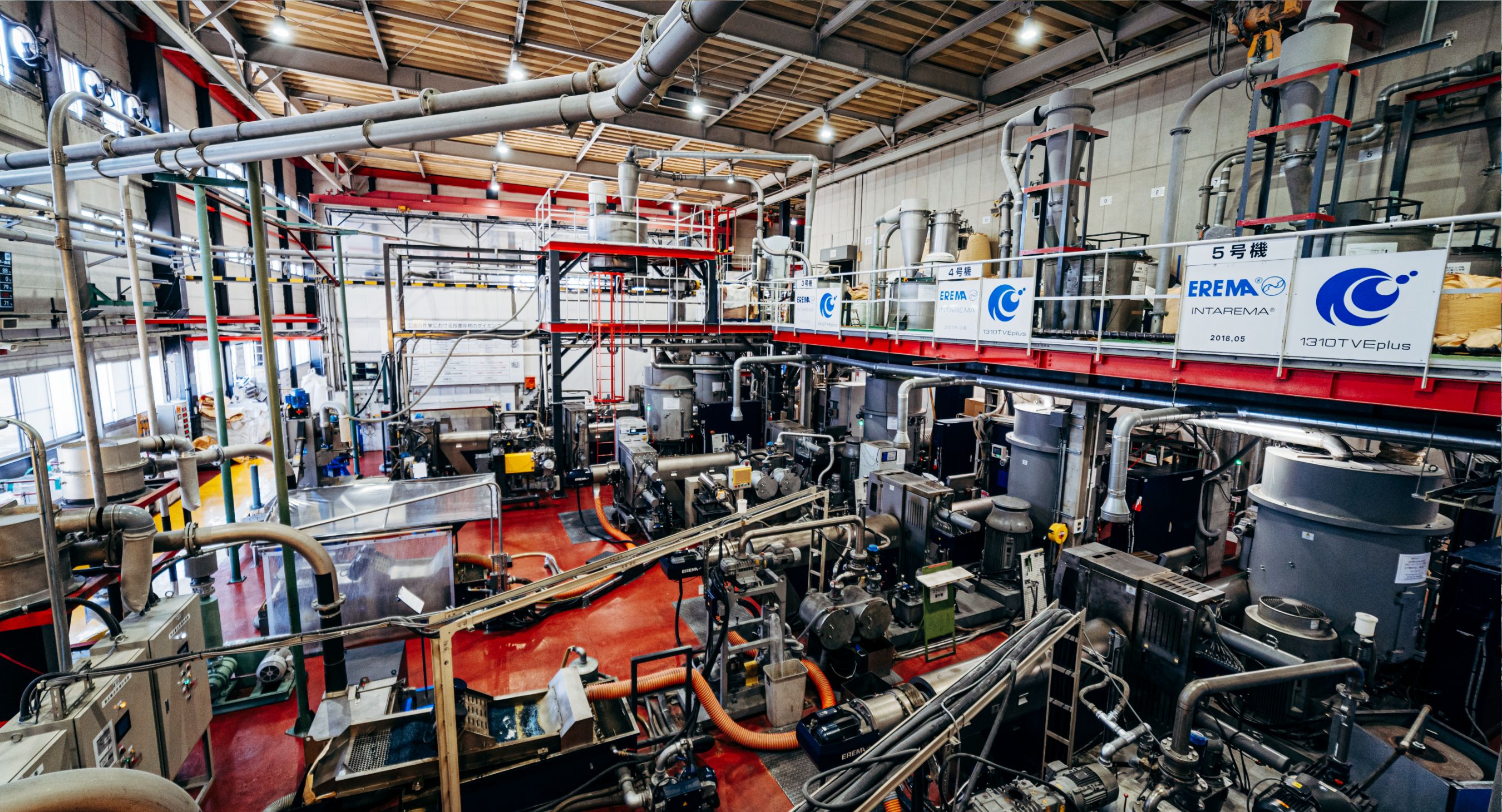

At Toyo Chemical, our primary mission is to consistently deliver “high-quality” products to our customers. Operating equipment based on human intuition and techniques can lead to quality variations. Therefore, Toyo Chemical is promoting machine automation—Smart Factory.

Toyo Chemical:

Committed to

Smart Factory Since 1994

To achieve consistent quality and supply volume, Toyo Chemical has introduced high-performance extrusion machine from Austria. Taking advantage of our factory relocation, we have implemented various automation measures such as remote management within the factory, and we continue to work daily toward realizing a smart factory.

Benefits of Smart Factory Implementation for

Customers and Society

Quality Improvement and Stabilization01

When quality confirmation relies on human judgement, variations arise due to individual sensory differences, resulting in inconsistent quality. To prevent this, we set numerical passing standards in machines and perform automated quality checks to maintain consistent quality.

Quality of raw materials is numerically

managed

in the monitoring room

Productivity Enhancement02

By introducing equipment that allows precise numerical tracking of production volumes and automating certain processes for 24-hour operation, we have achieved a monthly supply volume of 3,000 tons. This enables us to meet various customer needs, including large-volume orders.

Production volumes for each line are

constantly monitored on factory displays

CO2 Emission Reduction03

By visualizing power consumption and remotely controlling production line operations, we aim to create an environmentally friendly factory by reducing unnecessary electricity use. We are contributing to environmental improvement not only through our products (recycled plastic raw materials) but also by ensuring our work environment and equipment are designed with CO2 reduction in mind.

Power consumption is constantly monitored

by in-plant monitors

Towards further

smart factories

Towards further

smart factories

- • Robotics for plastic material feeding

- • Automated data analysis and collection

- • Promotion of Predictive maintenance

At Toyo Chemical, we aim to improve quality and productivity while reducing CO2 emissions through further smart factory implementation.

See other strengths of

Toyo Chemical

Plastic materials unused during the production process.

High-Quality

Recycled Plastic Materials

Environmentally friendly plastic raw materials

Proposal for CO2 Emission

Reduction Through

Recycled Pellet Usage

Processing Unused Plastic Materials and reusing them as raw materials

Contract Processing of Plastic Materials